South Devon College is working collaboratively with Torbay and South Devon NHS Foundation Trust, which runs Torbay Hospital, to urgently produce protective medical equipment to protect NHS staff in the fight against the COVID-19 virus.

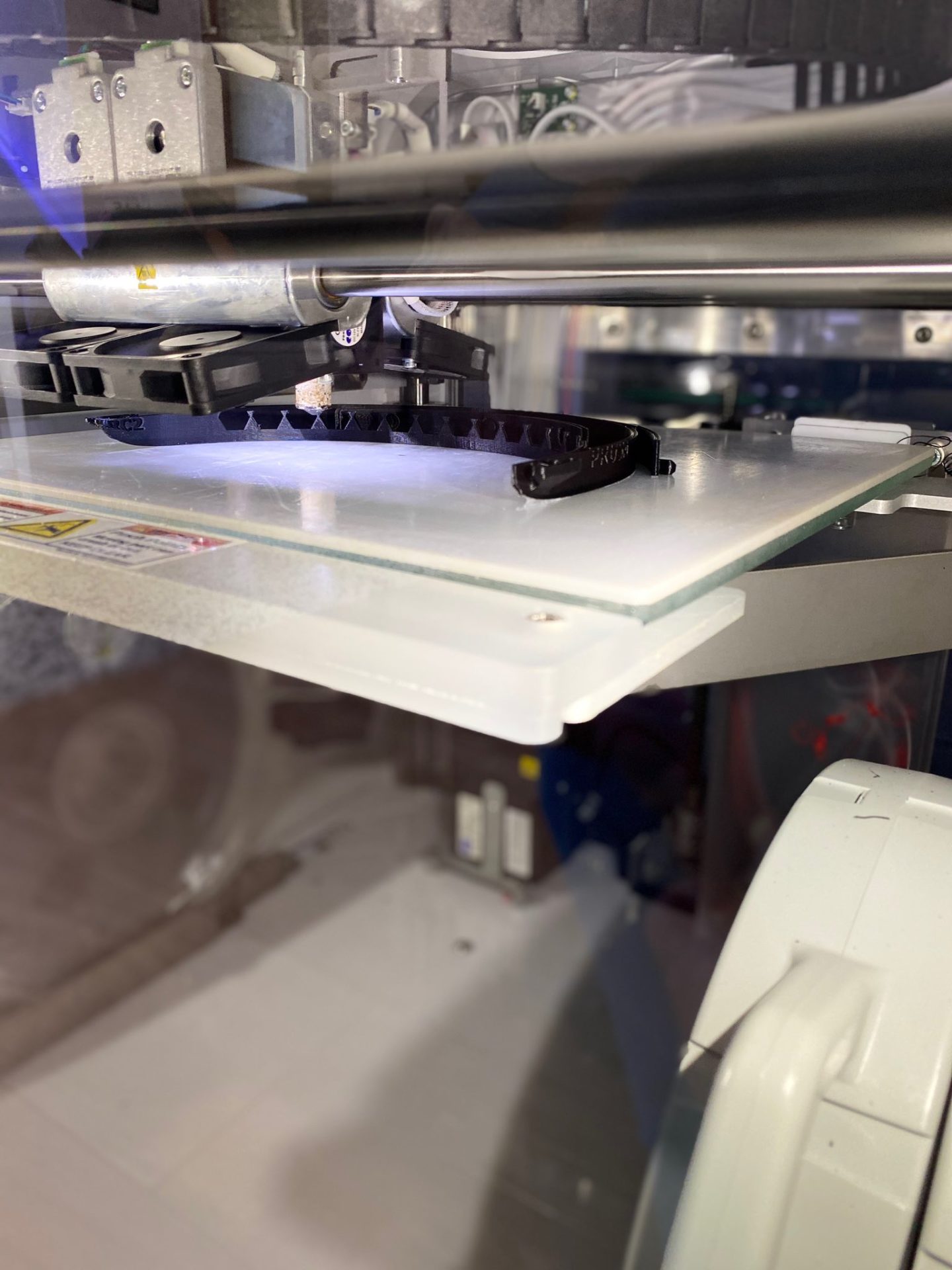

The team, based at the College’s Hi Tech & Digital Centre, are using state-of-the-art fused filament fabrication 3D printers to produce Face Shield Headbands. With limited access to the College’s Paignton campus, Engineering teaching staff including a PhD student, are working remotely on the production.

Following safety testing of the first prototype, the team are now working on producing around 100 face shields, which will be delivered to the team at Torbay Hospital.

Programme Coordinator in Hi-Tech Engineering at the College and PhD student, Ben Bryant, is leading the technical development of this project. For his PhD, he is researching how we can tackle the issue of contamination and sustainability of general thermoset plastic polymers. He wants to find a way we can recycle those plastics into 3D printing and additive manufacturing material for secondary use.

The College have called out to their extensive network of local business to support in this effort to support the NHS. They have engaged with Partington Print in Paignton who have kindly offered to cut, punch, and supply the clear visor element of the face mask. There is also going to be discussions with Darthaven Marina who will potentially be able to supply the elastic cord which will provide flexible adjustment to the visor head band.

Laurence Frewin, Principal and CEO at South Devon College said:

“We’re proud that our dedicated staff have been innovative and able to step up so quickly to support the call for help from our wonderful NHS at this time of national emergency.

“The Hi Tech & Digital Centre was always intended to provide a hub for the community, giving access to the latest technology and training for the people of South Devon and it’s great to see our excellent lecturers and technical specialists using not just the practical application of the skills they are teaching our students but also being great role models showing their values in playing a part in supporting the community of South Devon. They are really inspiring.

“It was never expected that the new Centre would ever need to play an essential role such as this but the fact that the equipment is now being used for such an important task is incredible. Along with many others, I want to thank the College staff and the local businesses that have taken this initiative with us.”

Adel Jones, Director of Transformation and Partnerships at Torbay and South Devon NHS Foundation Trust, said:

“It’s fantastic to have this level of innovation available locally. We cannot thank South Devon College enough for providing us with such fantastic support in producing the visors so quickly.

“We have been developing our partnership working with South Devon College over recent months and we’re now seeing the benefits of this collaborative working. Within two days of seeking support, the College team had produced a prototype which we could show our clinical teams, and we’re now in a position where we can start producing these at a greater volume.

“This is another example of the amazing response we’ve seen from our local community during these unprecedented times to keep our patients and staff safe.”

South Devon College staff also very quickly responded to the request made by Torbay Hospital on Wednesday 25th March and, on Thursday 26th March, had prepared 112 goggles, 187 safety glasses, 3 visors, 4 respirators, 9 boxes of disposable face masks, and 19 boxes of disposable gloves to be donated and were collected by NHS staff from the College’s Paignton campus.

Typically, Art and Digital Media use the 3D printers to make prototypes of their game characters, movie props, or products for their final year showcase. Marine use the 3D printers to build scaled models of boat hulls and propellers. But 3D printers have very quickly become an essential part of the manufacturing process producing prototypes in a short timeframe. They are even becoming the tool that creates the final products you see on shelves in the shop due to the rapid development of quality they can produce.

South Devon College are proud to lead this initiative, but they can’t do this alone. They’re inviting any local businesses with 3D printing capabilities to come forward and support this cause. They are also asking businesses who may be able to provide elasticated cord to get in touch.

If you can support South Devon College with this project and help protect our NHS, then contact Assistant Principal and Lead for Hi-Tech, Steve Caunter, by emailing [email protected].